תיאור

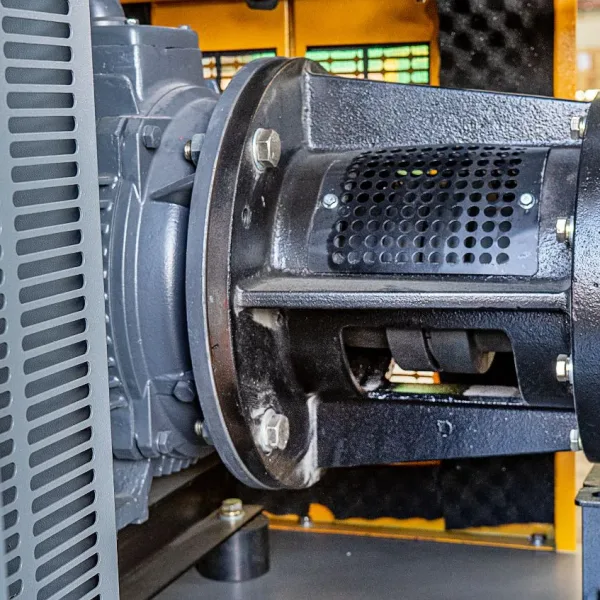

מדחסי אוויר נטולי שמן

הפתרון החסכוני עבור מספר רב של יישומים הדורשים אספקה רציפה של אוויר דחוס ללא שמן.

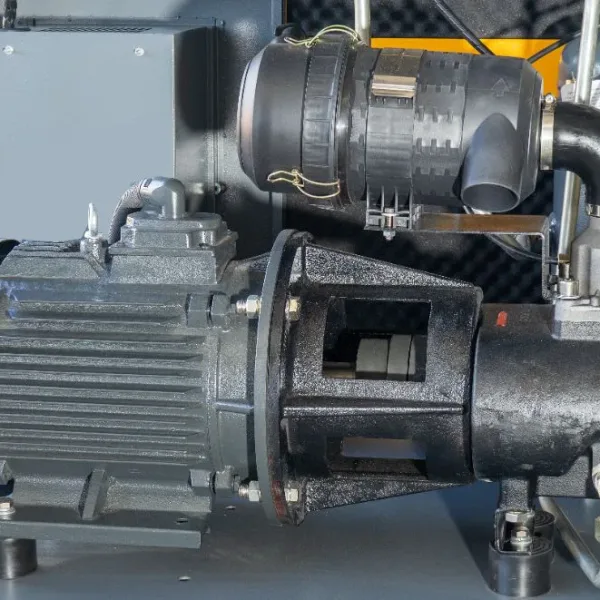

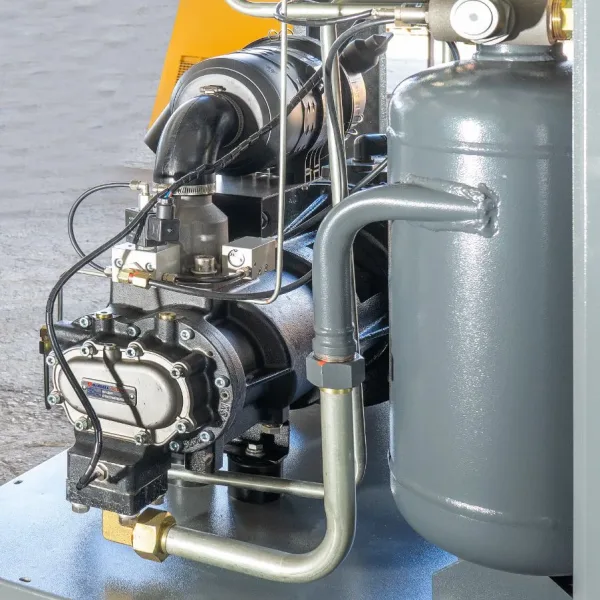

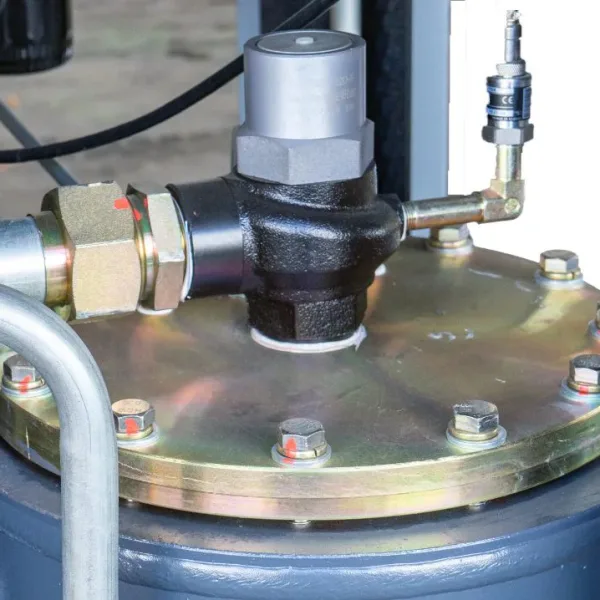

מדחסי אוויר נטולי שמן בנויים בטכנולוגיה חדשנית ובשיטות עבודה שונות: SCROLL/PUMP/SCREW/CENTRIFUGAL אוויר המסופק ממדחס נטול שמן צריך לעבור טיפול ע״י מייבש אוויר להורדת לחות.

ענפים רבים מחויבים במדחסים מסוג זה.

- מזון ומשקאות

- תחנות כוח

- מפעלים כימיים ופטרוכימיים

- מפעלי ביוטכנולוגיה ותרופות

- אלקטרוניקה וחלל

- טיפול בפסולת כימית

- בתי חולים ואוויר לנשימה

- מחזור ודחיסה של חנקן וגזים תואמים

דגמים ונתונים